Building a new demonstrator

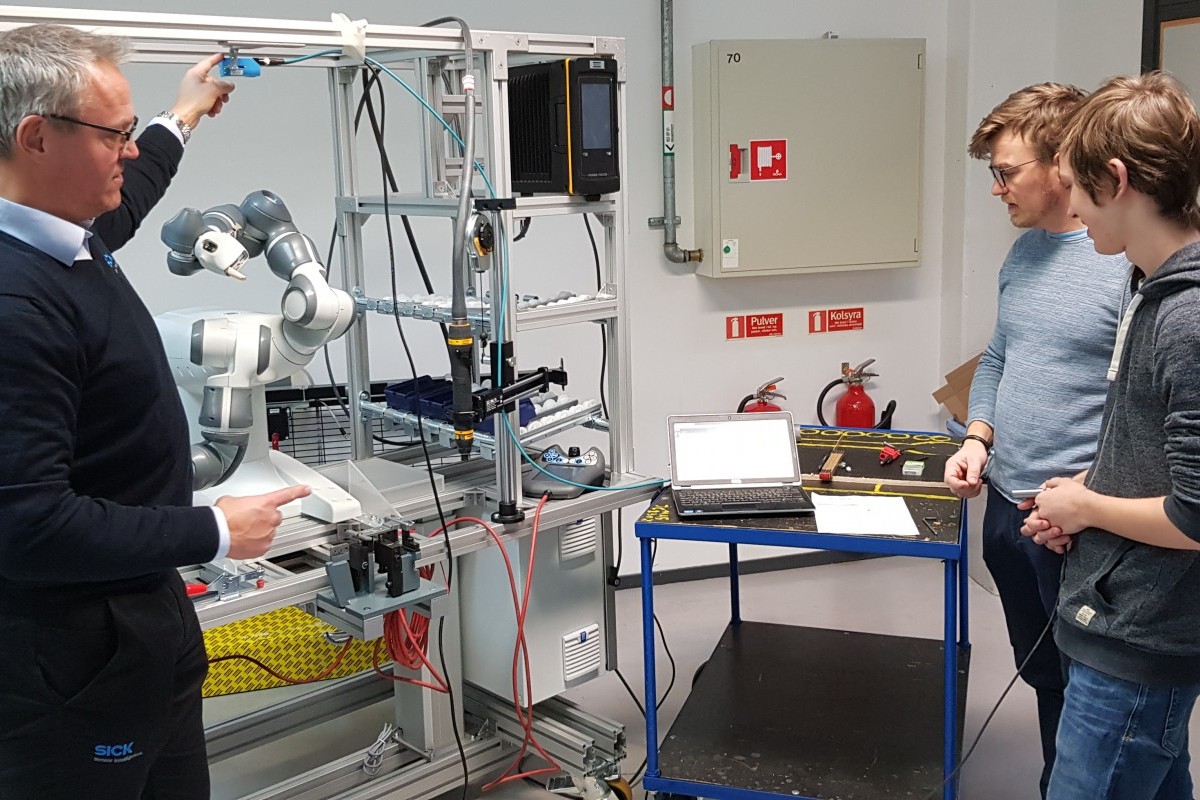

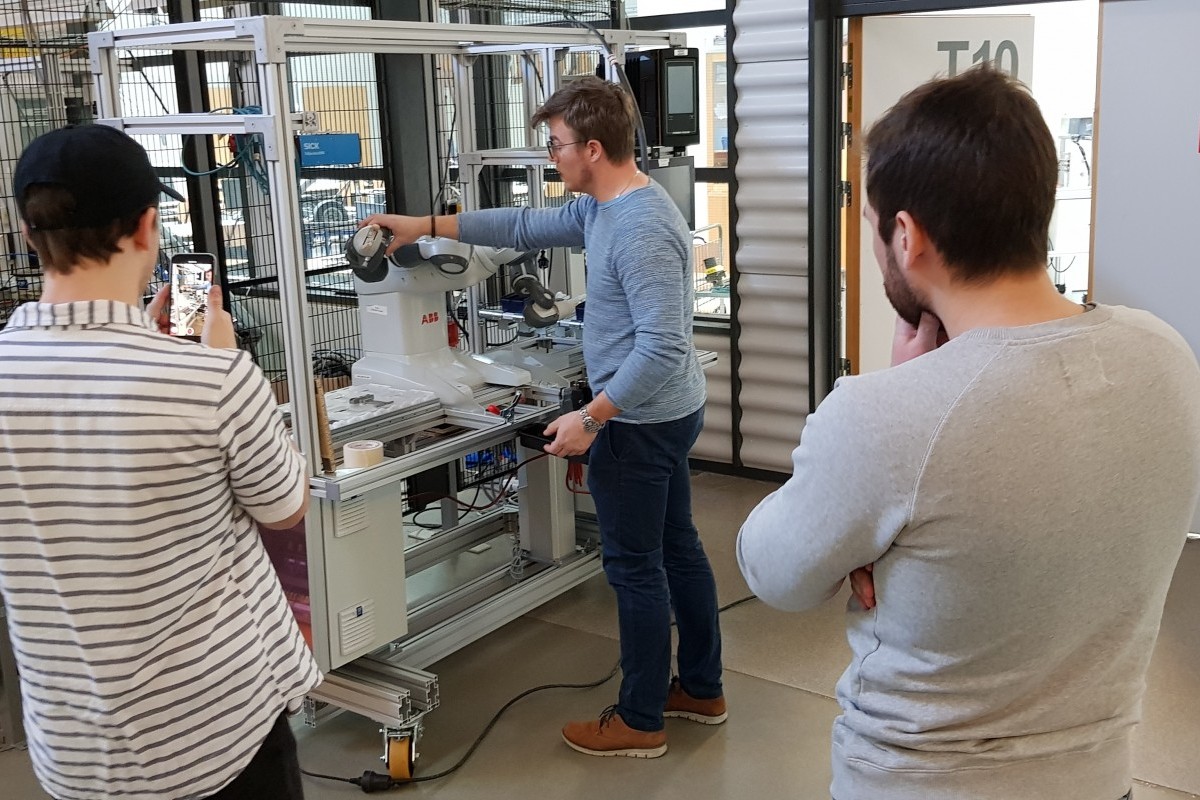

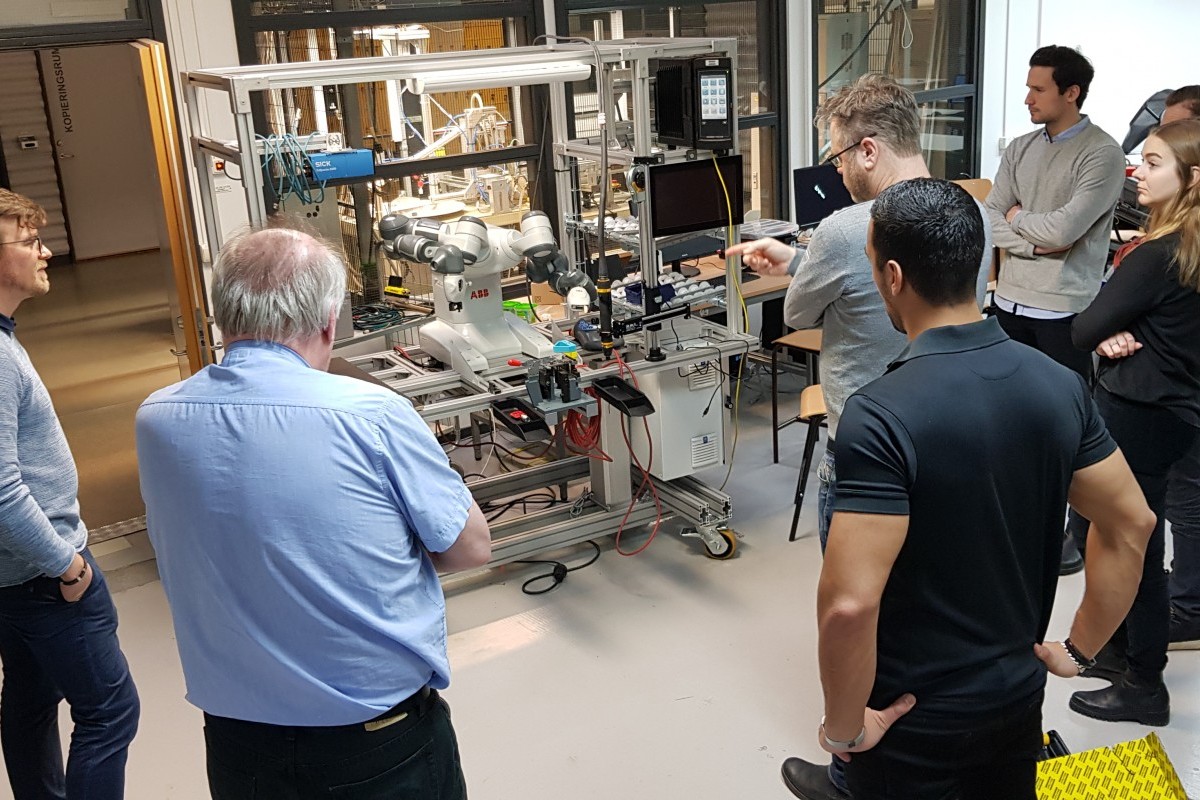

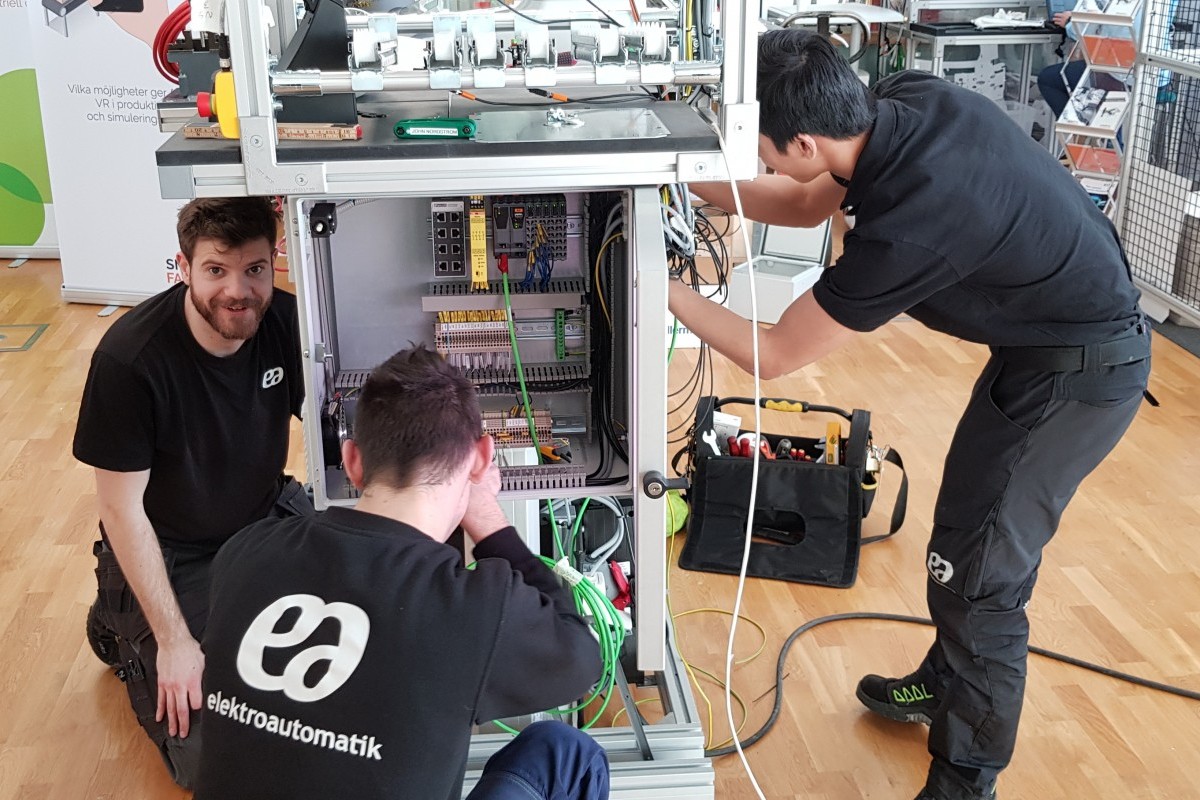

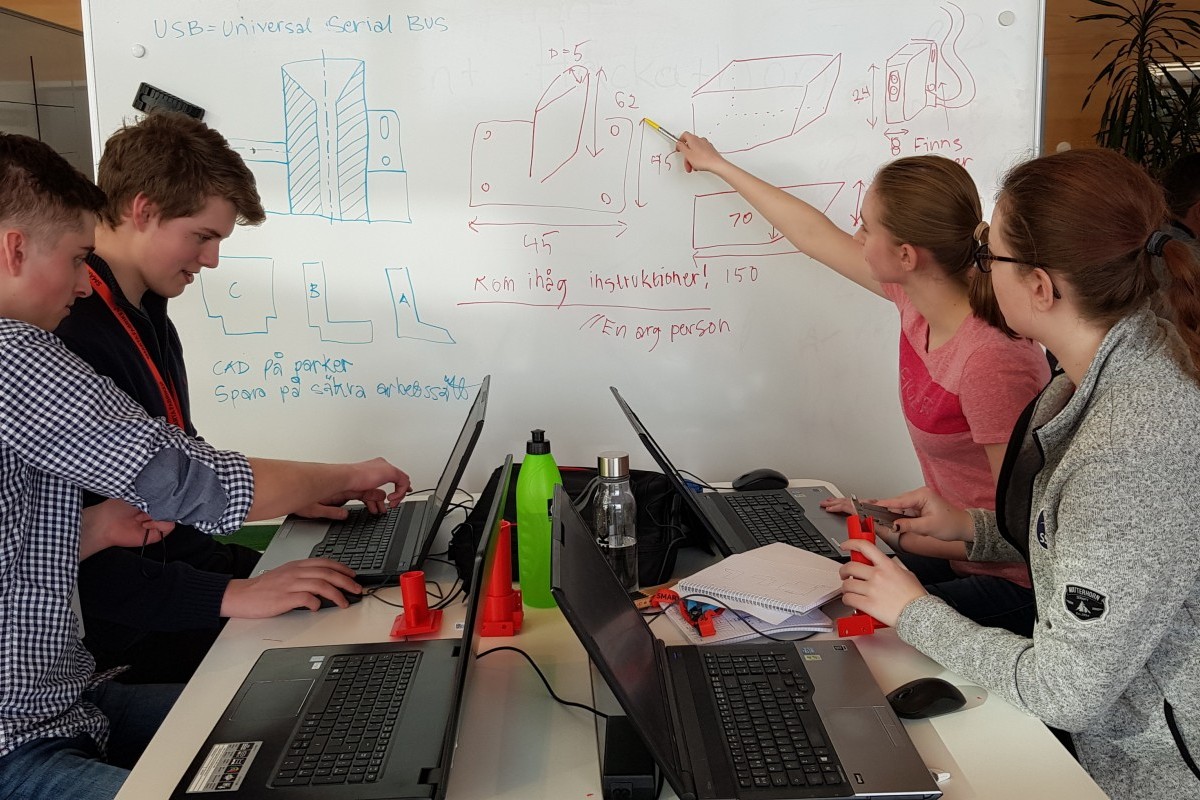

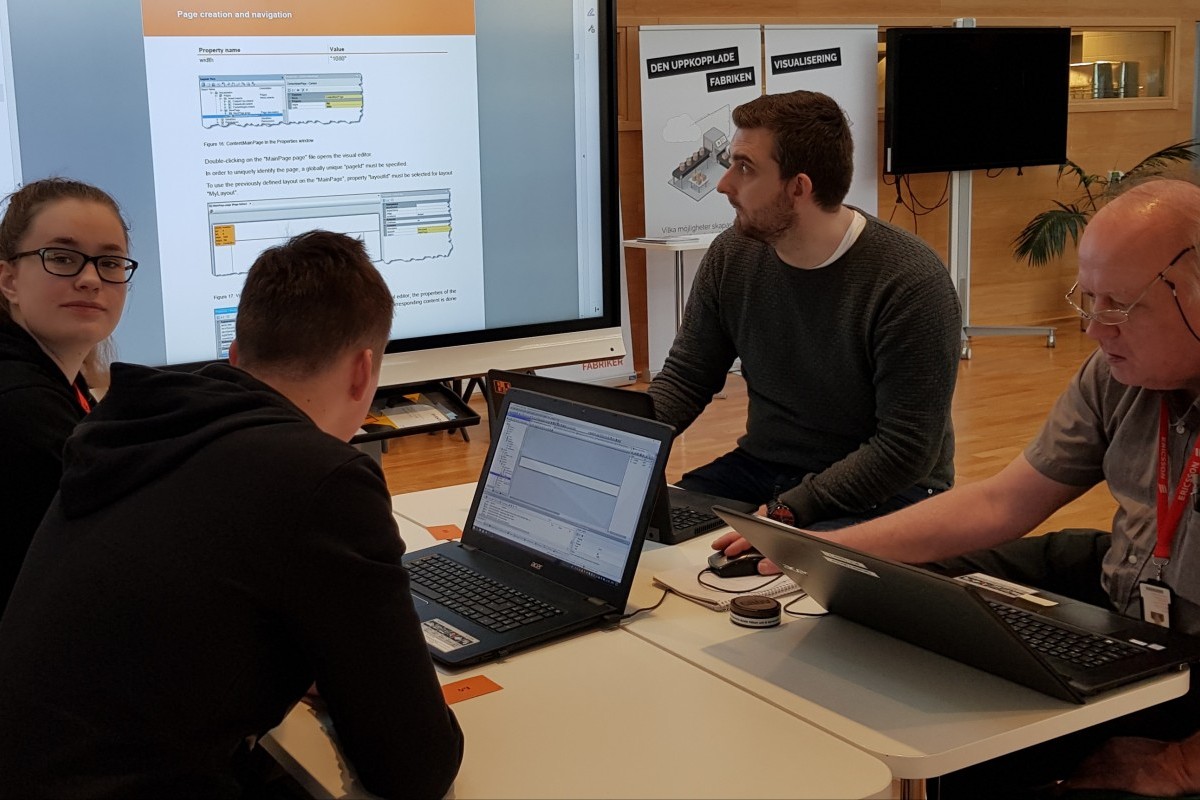

The best way to learn is to do. To learn more about industrial digitalization, we are building a new demonstrator of a smart factory with students supervised by companies.

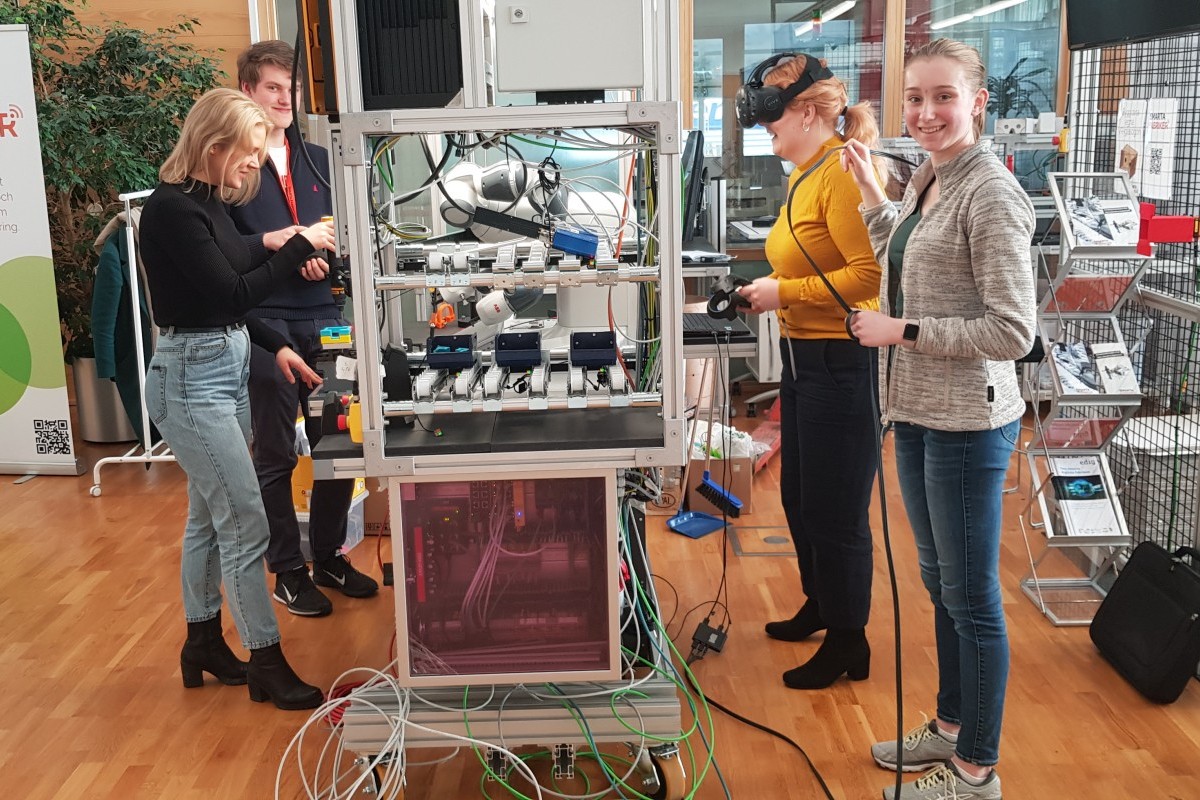

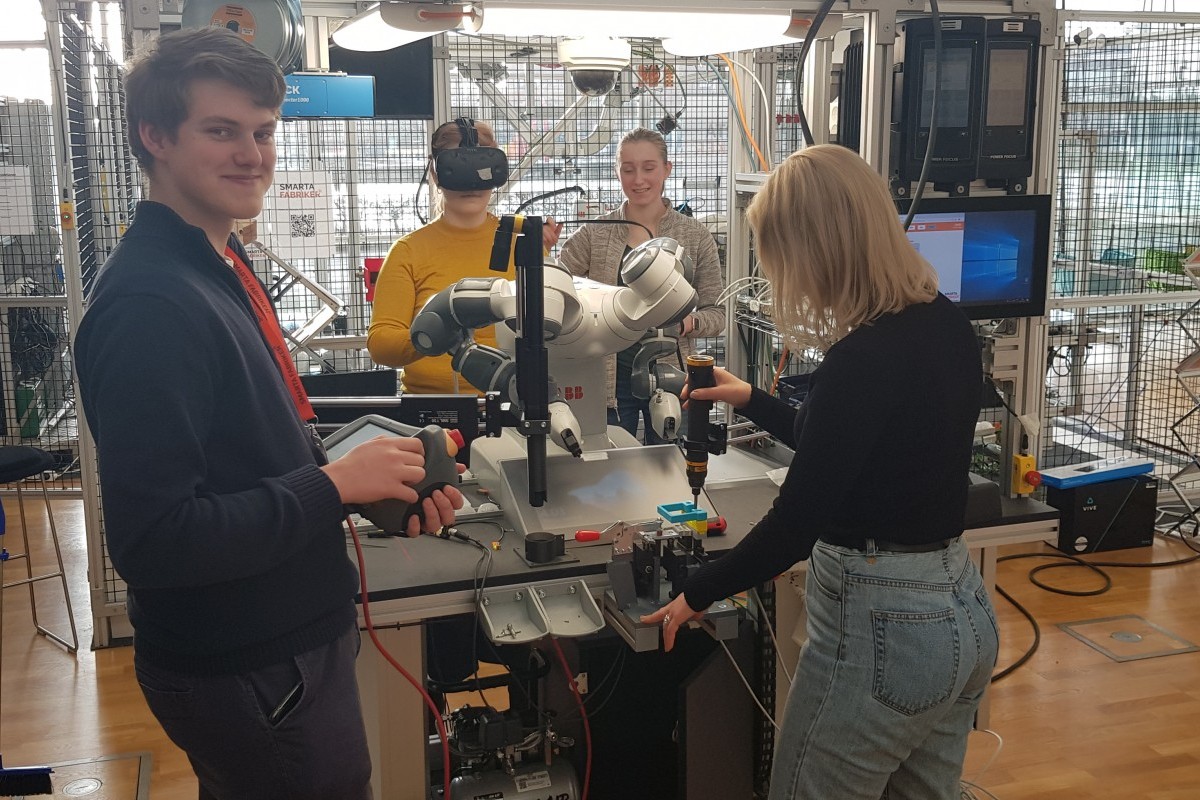

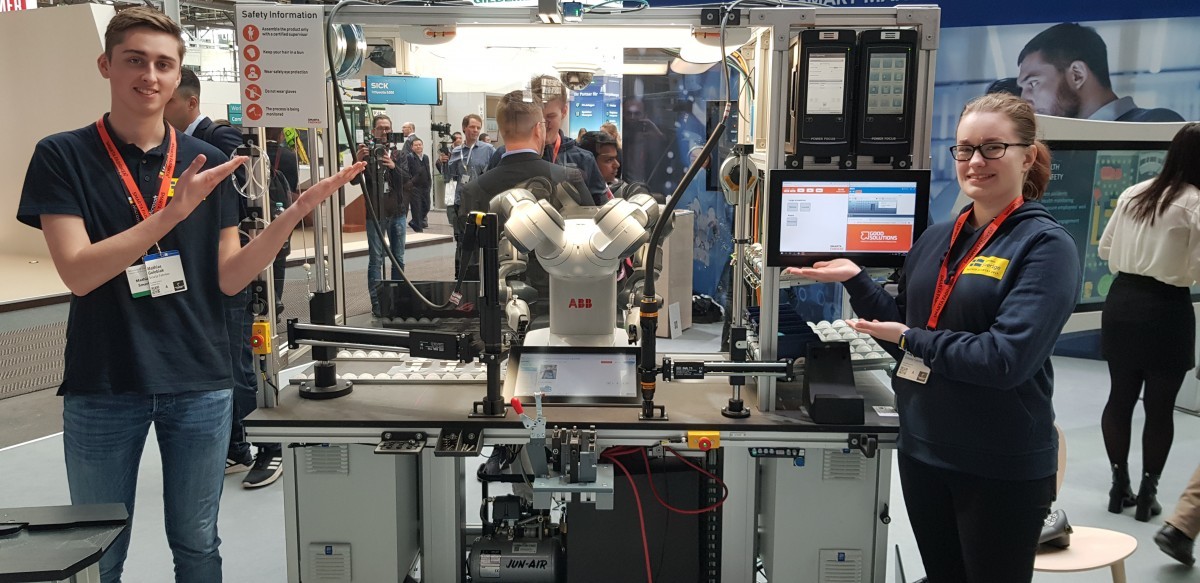

It started at the Hanover Fair in April 2018 with an idea of building a collaborative work station. A couple of thousand work hours later, the result can be seen at the Hannover Fair 1-5 April 2019. At the fair, visitors can assemble a product in collaboration with a Yumi.

The workstation is connected, we use 3D-printing to solve problems and there is a digital copy of the factory. In the new demonstrator, the goal is also to show a holistic perspective on digitalization. 18 students from the secondary high school, Göteborgsregionens Tekniska Gymnasium (GTG) are participating in the building. 12 students from Chalmers University of Technology are doing theire thesis work related to the demonstrator. 3 students from upper vocational training are updating the app.